Opportunities in eVTOLs

August 27, 2021

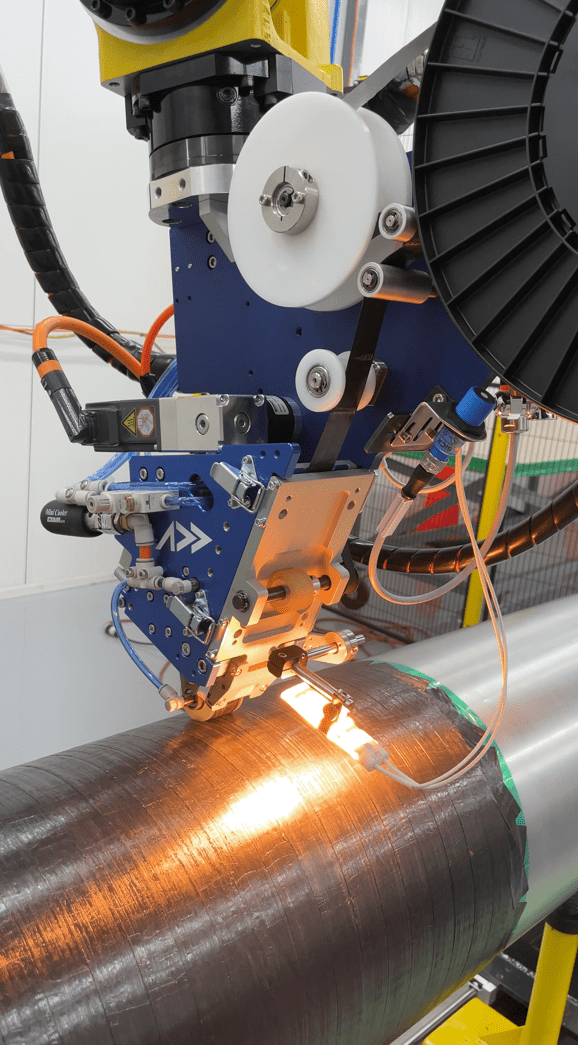

Defense (DoD) since 2013, including the integration of sensors and wiring into textile systems such as tents and uniforms. For the past two years, the company has extended this expertise into R&D efforts to integrate electrical systems into composite structures as well. As a result, Nautilus has developed processes for co-winding and soldering insulated conductors — like those used for connecting electronic devices inside an eVTOL — within individual threads or braided strips of Kevlar and other high-performance and heat-resistant materials. In May 2021, the company completed an Air Force-funded project with partners Goetz Composites (Bristol, R.I., U.S.) and the University of Rhode Island’s (URI, South Kingstown) Dynamic Photomechanics Laboratory and Multiscale Multiphysics Mechanics of Materials Research Laboratory to integrate electrical networks into carbon fiber composite airframes for eVTOLs. Nautilus’ braided Kevlar strips were molded into carbon fiber prepreg panels by Goetz Composites and tested in URI’s labs. Prototypes showed significant potential for weight savings and durability, Owens says.