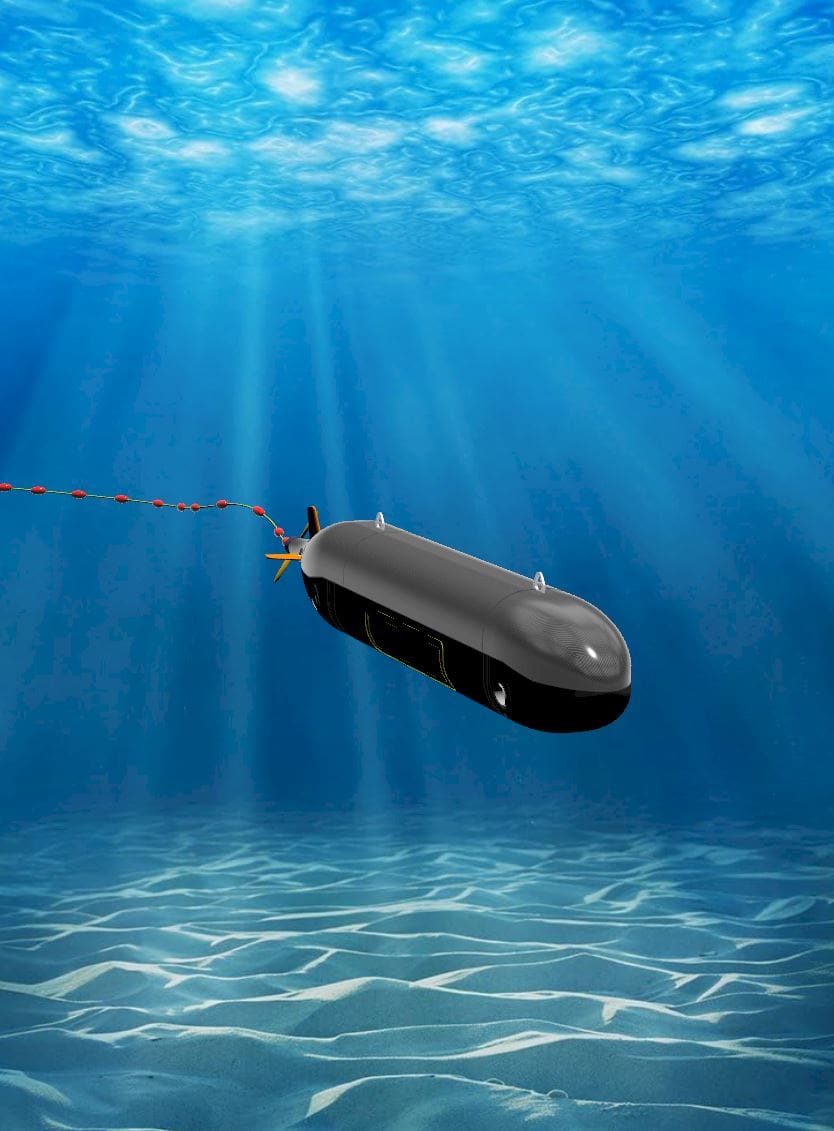

Powered, Zero Emission Water Transport

October 4, 2016

Earth’s natural resources are far too precious to be excessively consumed by combustion engines. In addition to quickly depleting resource supply levels, pollutants emitted from the consumption also have a detrimental effect on Earth. Today, most maritime activity depends heavily on legacy systems that burn a tremendous amount of hydrocarbons – pushing a heavy boat through the water takes a lot of effort! This unsustainable practice must change. Fortunately, recent technological advances have begun to increase the viability of alternative energy sources. As an industry, it is our responsibility to adopt these innovative technologies and assist in further development as we design and build next generation vessels.

Over the past few years, Goetz Composites and SDK Structures have been leading a team with one goal: design and build a light commercial boat that proves the viability of electric propulsion. To accomplish this, we have identified four key areas of focus:

State-of-the-Art Foiling Technology: In order to alleviate range anxiety, the boat must move through the water using minimal energy. In the past five years, there has been a huge leap forward in terms of the understanding and development of hydrofoils. The development of Computational Fluid Dynamics (CFD) models has followed suit, allowing for quick analysis of the control surfaces. Unfortunately, the most efficient control surfaces are inherently unstable.

Active Foiling: Before extremely efficient foil systems can be accessible to mainstream users, as opposed to elite America’s Cup athletes, an automated control system must be developed. Airplane pilots use a system of controls to make flying more intuitive. To further reduce error (induced by fatigue, etc.), autopilots do most of the work. An integrated control system like this enables central monitoring of critical systems (such as batteries, motors, and foil position), while constantly tracking performance. If a value is outside of safe operating parameters, the boat can land safely without issue.

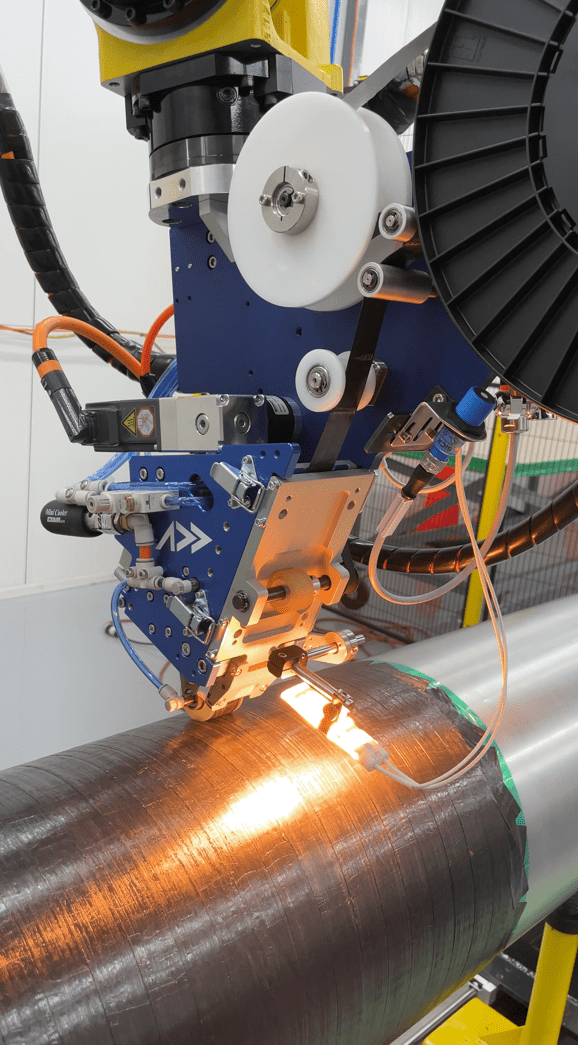

Lightweight Construction: Full prepreg carbon fiber construction and disciplined weight control enable maximum range and payload. Simply put: the lighter an object is, the less energy is required to move it.

Electric Propulsion: In order to maximize range, we are using batteries with extremely high specific energy that can be cooled without significant parasitic load. This technology is developing rapidly as many industries are seeing its value. Marine applications are specifically challenging due to higher required discharge rates, resulting in excessive heat.

We are excited to be working on this experiment in sustainability and look forward to collaborating with like-minded partners.